Bespoke Engineering

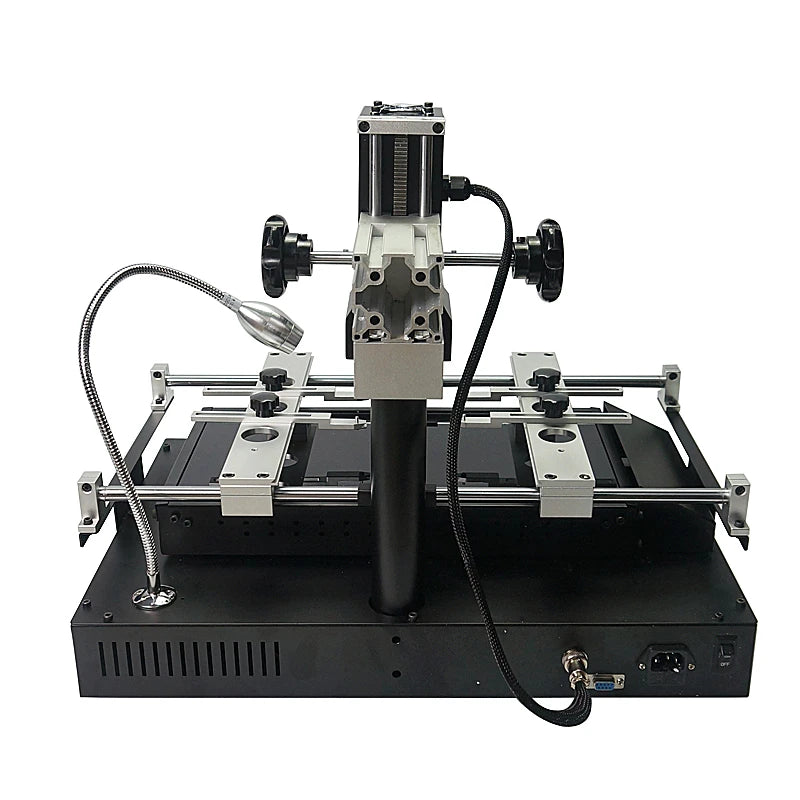

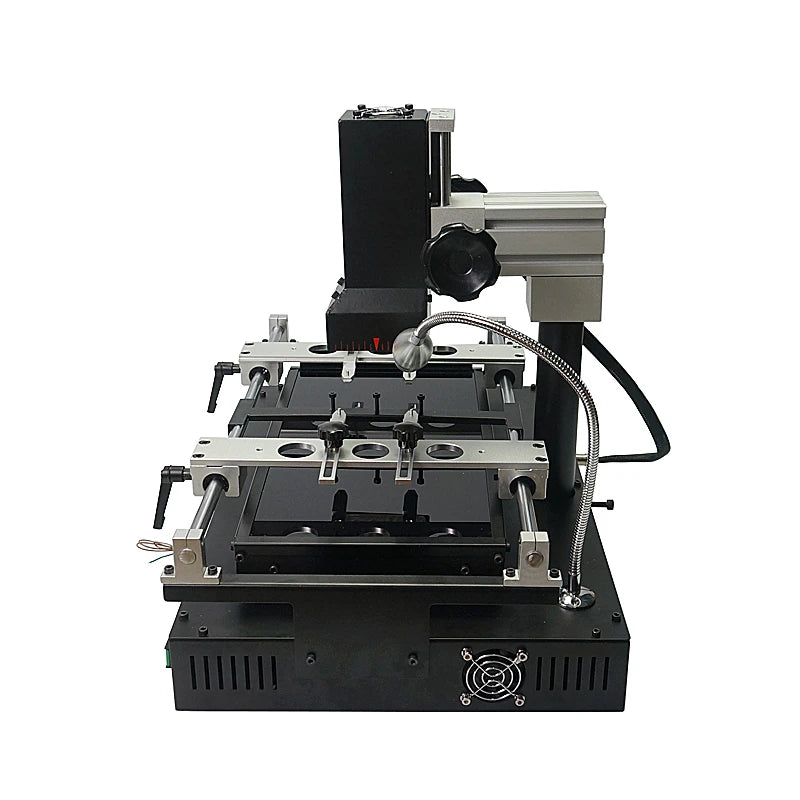

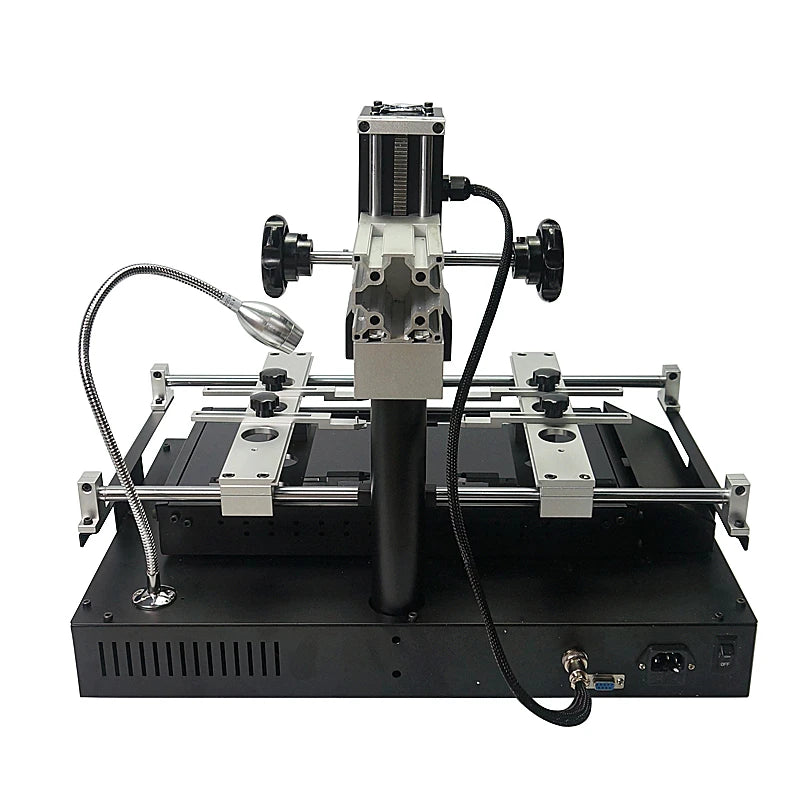

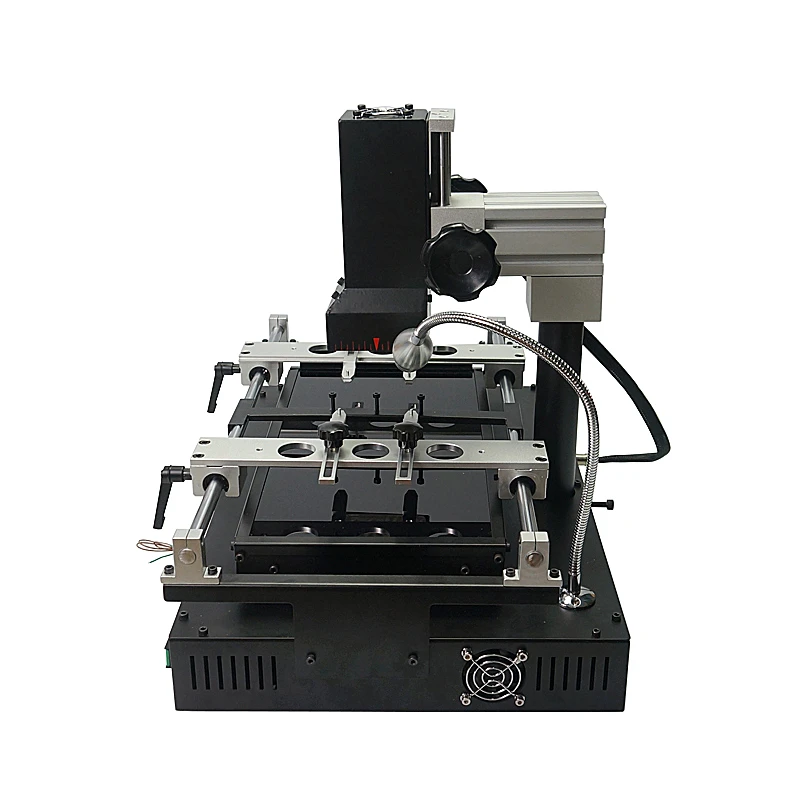

Infrared BGA Rework/IR Soldering Station Reballing Kit

Infrared BGA Rework/IR Soldering Station Reballing Kit

SPECIFICATIONS

Certification: CE

Model Number: ir8500 v.2

Operations: Manual / Software

Dimension: L780mmx W450mmx H260mm

Net Weight: 18kg

Power: 220V AC

Upper Heating: IR

Size of Upper heating: 80mm x 80mm

Consumption of upper heating: 450W

Size of Bottom heating: 400mm x200mm

General power: 2050W

Original official dark infrared Bga rework station bga solder station LY IR8500 V.2 BGA station with reball pack solder ball tweezer

CE Certification

can be connected to a computer

8 constant temperature segments

It can easily rework the variety of CPU's seat

Video: https://www.youtube.com/watch?v=8wTTk9LEnf8&feature=youtu.be

Features:

This is economic BGA model,substitute of IR-PRO-SC,if do small motherboard,can choose IR6500,if

do big board,can choose IR8500.

Introduction:

LY IR8500 Rework station for laptop motherboards, desktop computer motherboards, server boards, industrial computer boards, all kinds of game boards, communications equipment motherboards, LCD TVs and other large circuit board BGA rework.

LY IR8500 innovative designs an effective solution to general of infrared rework station vulnerable to the impact of air flow. will lead an inaccurate of temperature control can easily deal with lead-free soldering rework

Technical Parameters:

|

Basic Parameters |

|

|

Zones |

2 |

|

Heating |

IR |

|

Operations |

Manual / Software |

|

Dimension |

L780mmx W450mmx H260mm |

|

Weight |

18kg |

|

Total weight |

About 21 kg, vary with the different need of the users |

|

Electrical Parameters |

|

|

Power |

220V AC |

|

Upper Heating |

IR |

|

Size of Upper heating |

80mm x 80mm |

|

Consumption of upper heating |

450W |

|

Bottom Heating |

IR |

|

Size of Bottom heating |

400mm x200mm |

|

Consumption of Bottom heating |

1600W |

|

General power |

2050W |

|

Temperature Control |

|

|

Control mode of Upper |

Independent temperature control, high-precision closed-loop |

|

|

control, precision ± 0.5%, Alarm |

|

Control mode of Bottom |

Independent temperature control, high-precision closed-loop |

|

|

control, precision ± 0.5%, NO Alarm |

|

Rework Function |

|

|

SMD |

Suit for welding, remove or repair packaged devices |

|

|

such as BGA,PBGA,CSP,multi-layer |

|

|

metallic shield product and solder/lead |

|

Size of applicable chips |

≤70mm x70 mm |

|

Size of applicable PCB |

≤400mm x305mm |

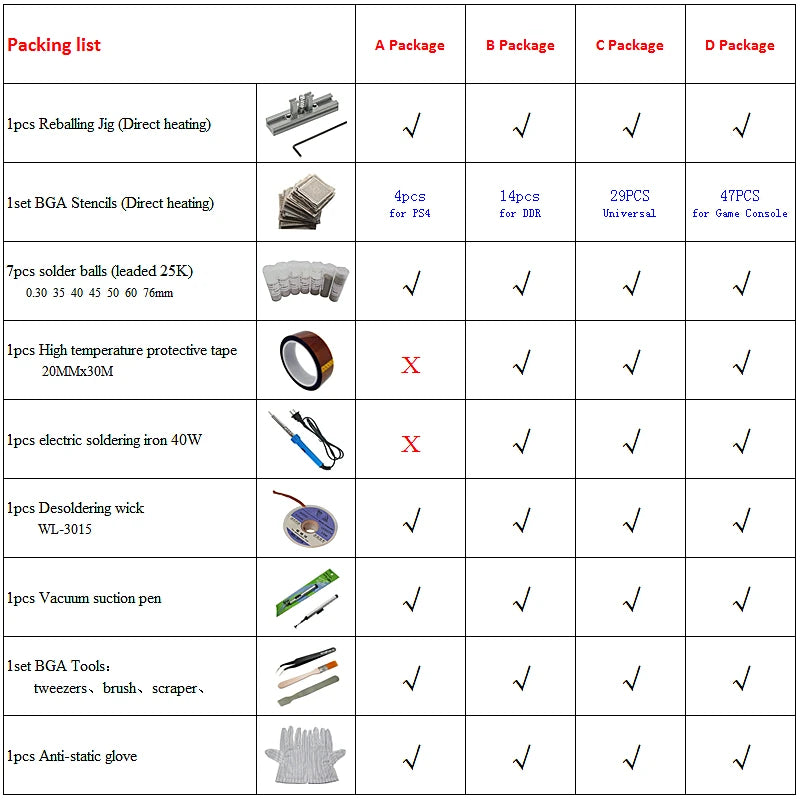

Packing list:

1× IR8500 BGA rework station

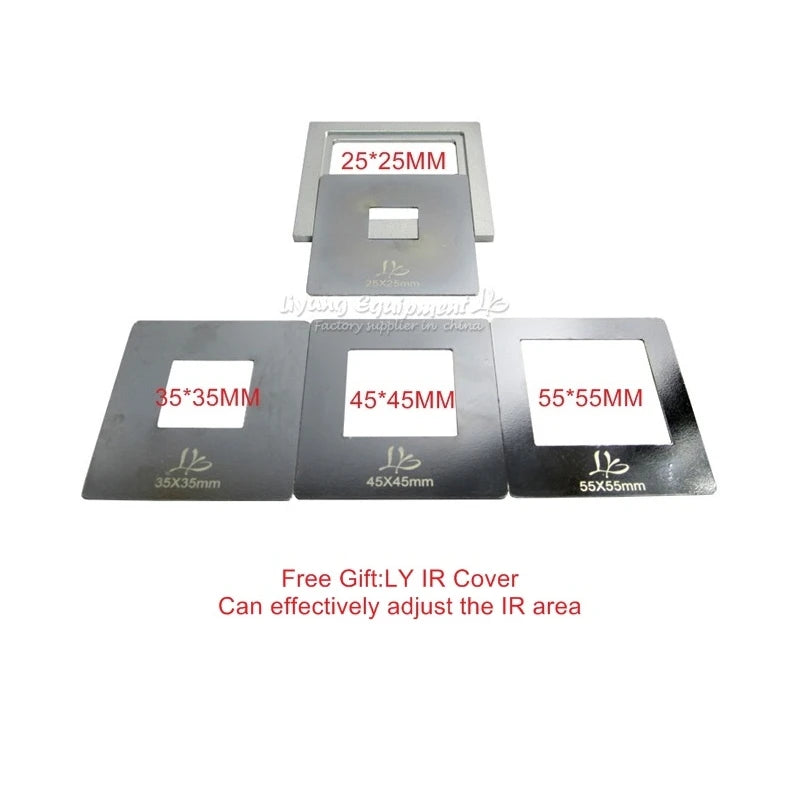

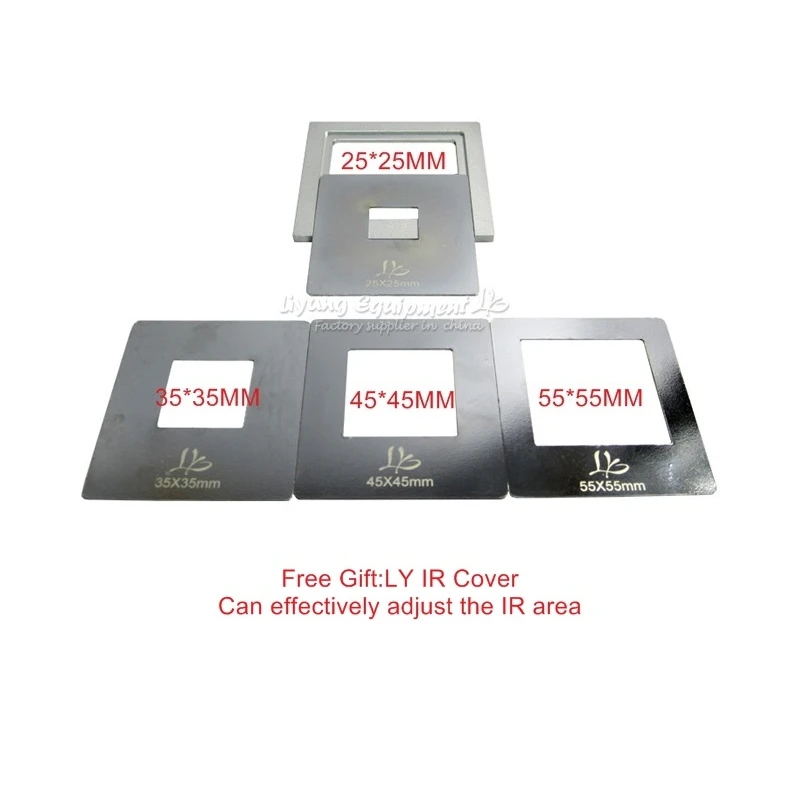

1x LY IR cover set

1× power cable

1× usb to rs232 port cable (with CD)

1× thermocouple

4x pcb jig with screw

1 x bottom support

1× CD of manual and software

1x gift (if you choose 'with gift ', package will have these bga parts )

(ABCD package , you can choose one ,We send C package by default)

Feature:

1.CE Certification

2.LY IR8500 Rework station for laptop motherboards, desktop computer motherboards, server boards, industrial computer boards, all kinds of game boards, communications equipment motherboards, LCD TVs and other large circuit board BGA rework.

3.LY IR8500 innovative designs an effective solution to general of infrared rework station vulnerable to the impact of air flow. will lead an inaccurate of temperature control can easily deal with lead-free soldering rework.

4.It can set up 8 rising temperature segments and 8 constant temperature segments to control. It can save 10 groups of temperature curves at one time.

5.It sensitive temperature measurement sensor to obtain an accurate and instantaneous temperature reading and monitoring.

6.The BGA rework station the technology of closed-loop temperature control ensures accurate temperature process and even heat distribution.

7.Machine overall system integration Design, Rework station more integrated workbench area occupied by smaller, Didn't mixed and disorderly of cables.

How to use

Please refer to the CD of USER MANUAL and to see how to use

Please refer to the SETTING OFTHE TEMPEATURE PARAMETERS MANUAL HERE and to see how to set temperature

Item Units and Pictures :

Couldn't load pickup availability

Share